-

AleksanderWiarygodni dostawcy

AleksanderWiarygodni dostawcy -

LouisMiło było z tobą pracować.

LouisMiło było z tobą pracować.

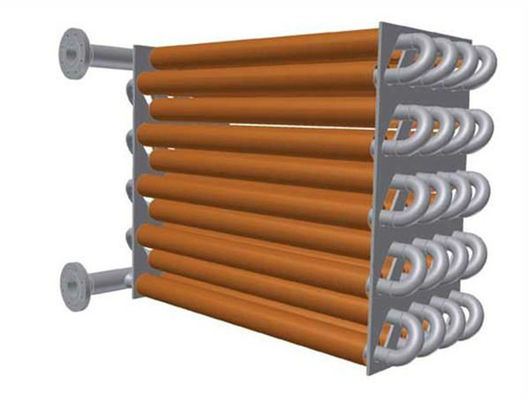

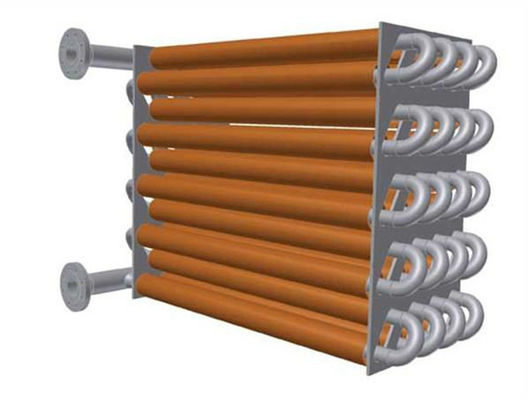

Wysokosprawny ekonomizer kotła z maks. wydajnością 20 t/h pary dla systemów naturalnej cyrkulacji elektrowni

Skontaktuj się ze mną o darmowe próbki i kupony.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Jeśli masz jakiekolwiek obawy, oferujemy 24-godzinną pomoc online.

x| Typ | Naturalne krążenie | Stosowanie | Elektrownia |

|---|---|---|---|

| Struktura | Rura wodna | Ciśnienie | Wysokie ciśnienie |

| Produkcja pary | Maks. 20 t/h | Styl | poziomy |

| Paliwo | Opalane węglem | Wyjście | Gorąca woda |

| Paliwo projektowe | Paliwo węglowe | Tworzywo | Specjalna tablica stalowa kotłowa |

| Typ paliwa | Gaz koksowy | Waga | 1-20 ton |

| Proces wytapiania | EF+LF + VD | Ut Standardowy | ASTM A388 lub EN10228 |

| Norma materiałowa | ASTM, en lub ISO | ||

| Podkreślić | Ekonomizer kotła o maks. wydajności 20 t/h,Ekonomizer kotła z naturalną cyrkulacją,Wymiennik ciepła elektrowni |

||

Ogrzewacze kotłowe to urządzenia wymiany ciepła z płetwami, które podgrzewają ciepła (zwykle wodę) do temperatury wrzenia, ale nie przekraczają jej.

- Sterownik ekonomiczny

- Wyroby z tworzyw sztucznych

- Wyroby z tworzyw sztucznych

W porównaniu z ekonomizerami z gołymi rurami, modele z rurami z płetwami H oferują:

- Zwiększona powierzchnia wymiany ciepła

- Zmniejszona liczba potrzebnych rur

- Rozszerzony obszar przepływu spalin w celu zmniejszenia prędkości przepływu i ścierania

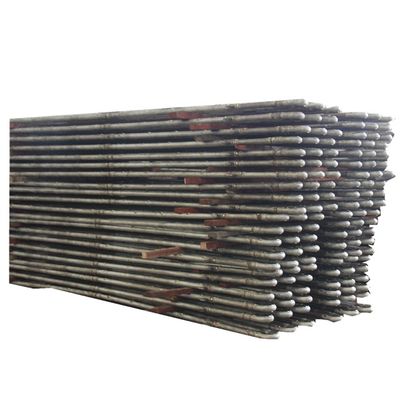

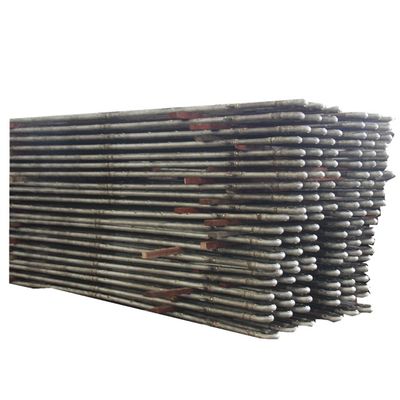

Nasze rury z płetwami H mogą być produkowane jako rury z podwójnymi płetwami H o wysokiej sztywności do zastosowań w długich rzędach rur.Ekonomizer o spirali wyposażony jest w nową konstrukcję z spiralnymi rurami płetw, aby przezwyciężyć problemy z ścieranie i wydłużyć żywotność.

| Opis | Elektryczne urządzenia |

| Materiał | Stal stopowa, stal węglowa, SA210C, SA213T22, itp. |

| Norma materiału | ASTM, EN lub ISO itp. |

| Wymiar | Zindywidualizowane |

| Waga | 10 ton - 1000 ton |

| Proces topienia | EF+LF+VD |

| Proces | Materiał→Włókno→Wrzutowanie na gorąco/zimno→Oprawa cieplna (normalizacja + hartowanie)→Inspekcja→przetwarzanie surowe→UT→Druga obróbka cieplna→przetwarzanie końcowe→Inspekcja |

| Standardy UT | ASTM A388 lub EN10228, itp. |

- Raport z badania uderzeniowego i obliczenia wytrzymałości z informacjami dotyczącymi zastosowanych materiałów

- 100% sprawozdania z badania NDT (bezniszczalnej kontroli) stali, rury i elektrody

- Sprawozdanie z badania rentgenowskiego, γ-promieniowego i ciekłego materiału penetrującego (szwy spawalnicze) w celu zapewnienia jakości kotła

- Sprawozdanie z badania hydraulicznego w celu weryfikacji standardowego ciśnienia roboczego i bezpieczeństwa

Adres:No.1 Dongli Road, Donglai, miasto Zhangjiagang, prowincja Jiangsu, Chiny

Tel:+86 (0) 512 5866 6196

Faks:+86(0) 512 5877 4453

Strona internetowawww.boilerfabrication.com