-

AleksanderWiarygodni dostawcy

AleksanderWiarygodni dostawcy -

LouisMiło było z tobą pracować.

LouisMiło było z tobą pracować.

Kotel gazowy ekonomizator wymiennik ciepła z rurami z płetwami do produkcji pary maks. 120 t/h i 1 roku gwarancji w naturalnym obiegu

Skontaktuj się ze mną o darmowe próbki i kupony.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Jeśli masz jakiekolwiek obawy, oferujemy 24-godzinną pomoc online.

x| Typ | Naturalne krążenie | Struktura | Rurka ognia i rura wodna |

|---|---|---|---|

| Ciśnienie | Niskie/wysokie ciśnienie | Produkcja pary | Max. 120t/h |

| Styl | Pionowy | Paliwo | Węgiel / Gaz / Ogrzewanie węglowe / Woda |

| Wyjście | Gorąca woda / para | Tworzywo | Stal węglowa, stal nierdzewna, stal stopowa |

| Norma materiałowa | ASTM, EN lub ISO itp. | Zakres masy | Min: 10 ton maksymalnie. 1000 ton |

| Proces wytapiania | EF+LF + VD | Proces | Materiał-> Wgat -> Hot/zimno -kołysanie-> Oczyszczanie cieplne (normalizacja+ temperowanie) |

| Ut Standardowy | ASTM A388 lub EN10228 itp. | Typ wymiennika ciepła | Ufinansowany ekonomizer rur |

| Typ rurki | podwójne biczówki | ||

| Podkreślić | Maks. 120 t/h Kotło ekonomiczne do produkcji pary,1 rok gwarancji wymiennika ciepła,Oszczędnik naturalnego obiegu spalin |

||

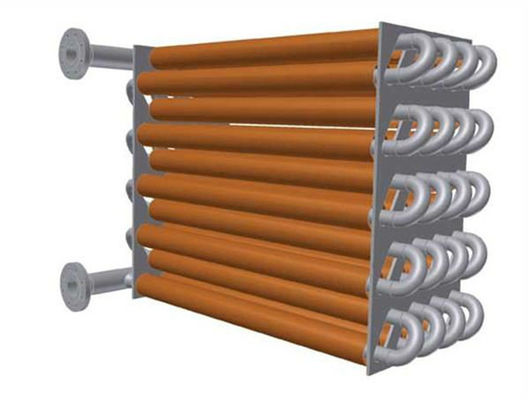

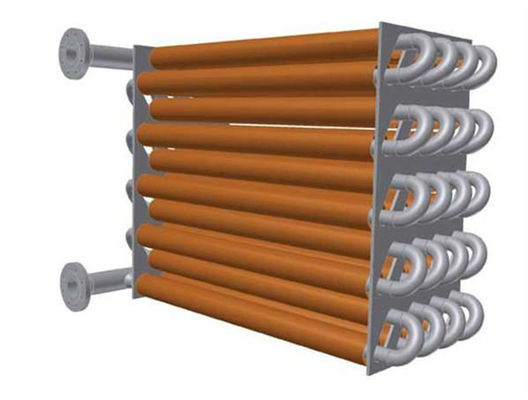

Ekonomaizery kotłowe to wysokowydajne urządzenia do wymiany ciepła z rurami ożebrowanymi, zaprojektowane do podgrzewania cieczy (zazwyczaj wody) bez przekraczania punktu wrzenia cieczy. Produkujemy trzy rodzaje ekonomizerów kotłowych:

- Ekonomizer z rurami gładkimi

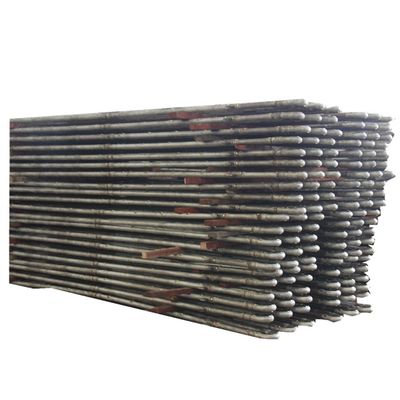

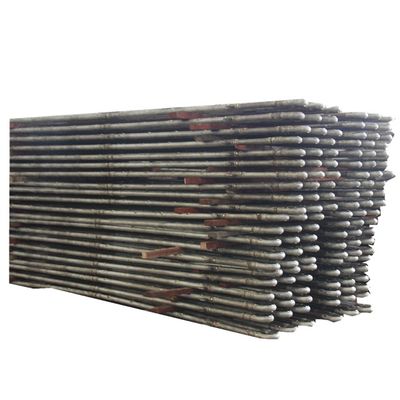

- Ekonomizer z rurami ożebrowanymi typu H

- Ekonomizer z rurami ożebrowanymi spiralnie

Ekonomizer z rurami ożebrowanymi typu H to szczególnie wydajna konstrukcja składająca się z rur ożebrowanych typu H. W porównaniu z ekonomizerami z rurami gładkimi, modele z rurami ożebrowanymi typu H oferują kilka zalet:

- Zwiększona powierzchnia wymiany ciepła

- Zmniejszona liczba wymaganych rur

- Rozszerzona powierzchnia przepływu spalin w celu zmniejszenia prędkości przepływu i ścierania

- Dostępne w konfiguracji z podwójnymi rurami ożebrowanymi typu H dla zwiększonej sztywności w długich rzędach rur

Ekonomizer spiralny z ożebrowaniem reprezentuje naszą najnowszą innowację w zakresie projektowania, charakteryzującą się rurami z ożebrowaniem spiralnym, które skutecznie rozwiązują problemy związane ze ścieraniem i wydłużają żywotność.

| Opis | Ekonomizer kotłowy |

|---|---|

| Materiał | Stal stopowa, stal węglowa, SA210C, SA213T22 itp. |

| Standard materiałowy | ASTM, EN lub ISO itp. |

| Wymiar | Dostosowanie |

| Waga | Min: 10 ton Maks.: 1000 ton |

| Proces wytapiania | EF+LF + VD |

| Proces | Materiał→Wlewki → Walcowanie na gorąco/zimno→ Obróbka cieplna (normalizacja + hartowanie) → Kontrola → obróbka zgrubna→UT →2. Obróbka cieplna →obróbka wykańczająca →Kontrola |

| Standard UT | ASTM A388 lub EN10228 itp. |

- Raport z testu udarności i obliczeń wytrzymałościowych z informacjami o zastosowanych materiałach

- 100% raport NDT (badania nieniszczące) płyty stalowej, rury i elektrody

- Raport z badań rentgenowskich, γ-promieniowych i penetracyjnych (spoiny spawalnicze) w celu zapewnienia pełnej jakości kotła

- Raport z testu hydraulicznego w celu weryfikacji standardowego ciśnienia roboczego i bezpieczeństwa