-

AleksanderWiarygodni dostawcy

AleksanderWiarygodni dostawcy -

LouisMiło było z tobą pracować.

LouisMiło było z tobą pracować.

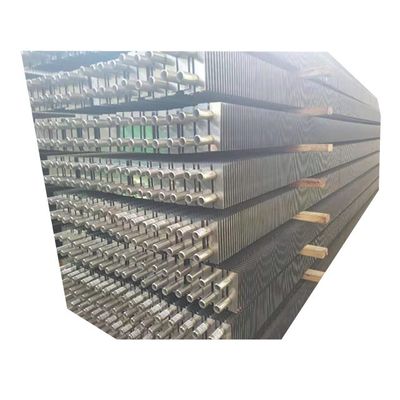

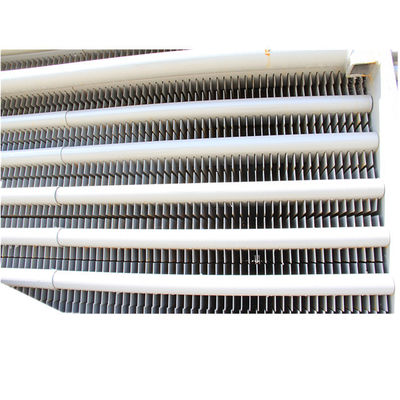

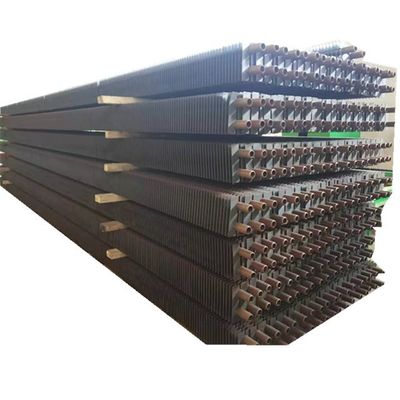

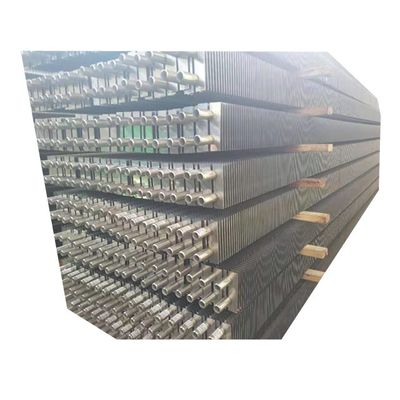

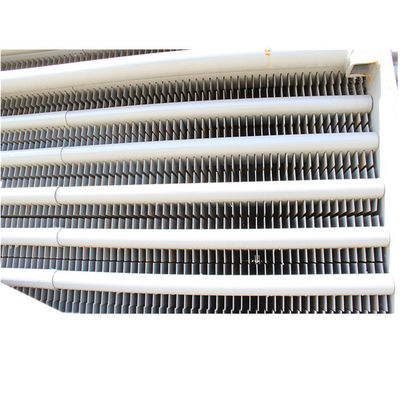

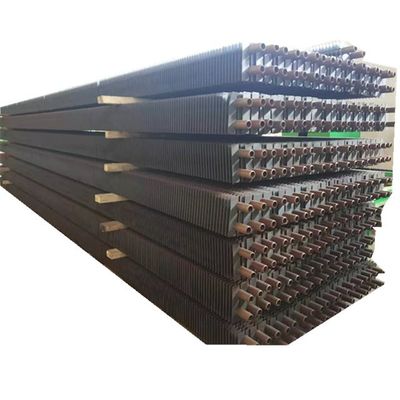

H Fin Tube Economizer z maksymalną produkcją pary 20t/h 1 rok gwarancji i 5 lat gwarancji na podstawowe komponenty

Skontaktuj się ze mną o darmowe próbki i kupony.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Jeśli masz jakiekolwiek obawy, oferujemy 24-godzinną pomoc online.

x| Typ | Naturalne krążenie | Struktura | Rurka ognia i rura wodna |

|---|---|---|---|

| Ciśnienie | Niskie/wysokie ciśnienie | Produkcja pary | Maks. 20 t/h |

| Styl | Pionowy | Paliwo | Węgiel / Gaz / Ogrzewanie węglowe / Woda |

| Wyjście | Gorąca woda / para | Obróbka powierzchniowa | Namalowany |

| Tworzywo | Stalowa stal, stal węglowa, SA210C, SA213T22 | Norma materiałowa | ASTM, en lub ISO |

| Zakres masy | 10 ton - 1000 ton | Proces wytapiania | EF+LF + VD |

| Proces | Materiał-> Ingot-> Hot/Cold-Rolling-> Oczyszczanie cieplne-> Kontrola-> Szorstka obró | Ut Standardowy | ASTM A388 lub EN10228 |

| Typ wymiennika ciepła | Ufinansowany ekonomizer rur | ||

| Podkreślić | Max 20t/h Produkcja pary H Fin Tube Economizer,1 rok gwarancji H Fin Tube Economizer,5 lat gwarancja na podstawowe komponenty H Fin Tube Economizer |

||

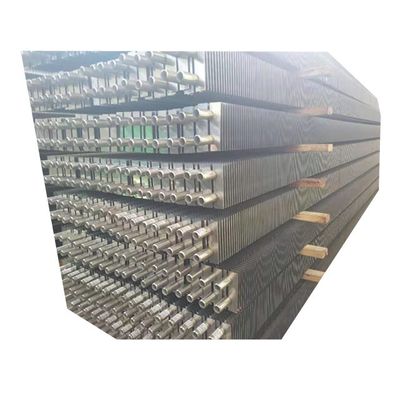

Ekonomizatory kotłowe to wysokiej wydajności urządzenia wymiany ciepła z rurami z płetwami, przeznaczone do ogrzewania cieczy (zwykle wody) bez osiągania temperatury wrzenia.Produkujemy trzy rodzaje ekonomizerów kotłowych:

- Sterownik ekonomiczny

- H ekonomizer rury z płetwami

- Wyroby z tworzyw sztucznych

- Zwiększa powierzchnię wymiany ciepła przy jednoczesnym zmniejszeniu liczby potrzebnych rur

- Zwiększa powierzchnię przepływu spalin w celu zmniejszenia prędkości przepływu i ścierania

- Dostępny w konfiguracji rury z podwójnym płetwem H dla zwiększonej sztywności w długich rzędach rur

- Wyższa niż konstrukcja gołych rur pod względem wydajności i trwałości

Oszczędnik znacząco obniża koszty chłodzenia poprzez optymalizację efektywności przenoszenia ciepła, umożliwiając wyłączenie sprężarki przy zachowaniu odpowiedniej mocy chłodzenia.

| Opis | Elektryczne urządzenia |

|---|---|

| Materiał | Stal stopowa, stal węglowa, SA210C, SA213T22 |

| Norma materiału | ASTM, EN lub ISO |

| Wymiar | Dostosowywalne |

| Waga | 10-1000 ton |

| Proces topienia | EF+LF+VD |

| Proces produkcji | Materiał→Włókno→Walcowanie na gorąco/zimno→Opracowanie cieplne→Inspekcja→Ruchy obróbki maszynowej→UT→Druga obróbka cieplna→Opracowanie końcowe→Wypatrzenie końcowe |

| Standardy UT | ASTM A388 lub EN10228 |

- Sprawozdania z badań uderzeniowych i obliczeń wytrzymałości z informacjami dotyczącymi materiałów

- 100% NDT (badania nieniszczące) stali, rur i elektrod

- Badanie rentgenowskie, γ-promieniowe i badania płynnego materiału penetrującego dla wszystkich szwów spawalniczych

- Sprawozdania z badań hydraulicznych w celu weryfikacji ciśnienia roboczego i norm bezpieczeństwa