-

AleksanderWiarygodni dostawcy

AleksanderWiarygodni dostawcy -

LouisMiło było z tobą pracować.

LouisMiło było z tobą pracować.

Ekonomizer kotła z rurami ożebrowanymi typu H z maksymalną produkcją pary 20 t/h, 1 rok gwarancji i 5 lat gwarancji na główne komponenty

Skontaktuj się ze mną o darmowe próbki i kupony.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Jeśli masz jakiekolwiek obawy, oferujemy 24-godzinną pomoc online.

x| Typ | Naturalne krążenie | Struktura | Rurka ognia i rura wodna |

|---|---|---|---|

| Ciśnienie | Niskie/wysokie ciśnienie | Produkcja pary | Maks. 20 t/h |

| Styl | Pionowy | Paliwo | Węgiel / Gaz / Ogrzewanie węglowe / Woda |

| Wyjście | Gorąca woda / para | Obróbka powierzchniowa | Namalowany |

| Tworzywo | Stalowa stal, stal węglowa, SA210C, SA213T22 | Norma materiałowa | ASTM, en lub ISO |

| Zakres masy | 10 ton do 1000 ton | Proces wytapiania | EF+LF+VD |

| Proces | Materiał-> Ingot-> Hot/Cold-Rolling-> Oczyszczanie cieplne-> Kontrola-> Szorstka obró | Ut Standardowy | ASTM A388 lub EN10228 |

| Obróbka cieplna | Normalizacja+ temperowanie | ||

| Podkreślić | Ekonomizer kotła o wydajności pary maks. 20 t/h,1 rok gwarancji na rury ożebrowane typu H,5 lat gwarancji na główne komponenty ekonomizera kotła |

||

Wysokiej wydajności ekonomizer kotłowy zaprojektowany jako rezerwowe części statku ekonomizer gazu wydechowego, wyprodukowany zgodnie z normami ASME do zastosowań w elektrowniach.

Gospodarcze kotłowe to urządzenia wymiany ciepła z płetwami, które ogrzewają cieczy (zwykle wodę) bez przekraczania temperatury wrzenia cieczy.

- Sterownik ekonomiczny

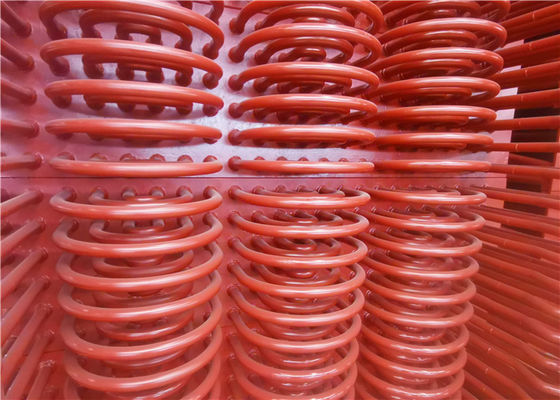

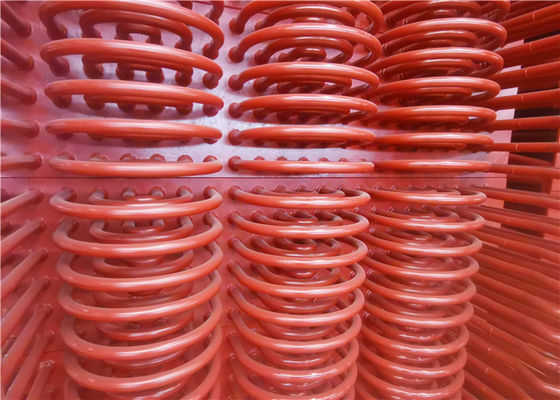

- H ekonomizer rury z płetwami

- Wyroby z tworzyw sztucznych

W porównaniu z ekonomizerami na gołym rurze, ekonomizery na rurze H oferują:

- Większy obszar wymiany ciepła z mniejszą liczbą rur

- Zwiększona powierzchnia przepływu spalin w celu zmniejszenia prędkości przepływu i ścierania

- Opcja dla rzędów długich rur z podwójnymi płetwami H o wysokiej sztywności

Ekonomizer z płetwami spiralnymi wyposażony jest w nowo zaprojektowany sprzęt do przenoszenia ciepła z spiralnymi rurami płetw, aby przezwyciężyć problemy z ścieranie i wydłużyć żywotność.

Oszczędnik zmniejsza koszty chłodzenia, umożliwiając wyłączenie sprężarki przy zachowaniu odpowiedniego chłodzenia, co powoduje znaczne oszczędności energii.

| Opis | Elektryczne urządzenia |

|---|---|

| Materiał | Stal stopowa, stal węglowa, SA210C, SA213T22, itp. |

| Norma materiału | ASTM, EN lub ISO itp. |

| Wymiar | Dostosowanie |

| Waga | Min: 10 ton Maks.:1000 ton |

| Proces topienia | EF+LF + VD |

| Proces | Materiał→Włókno →Wrzutowanie na gorąco/zimno→Oprawa cieplna (normalizacja + hartowanie) →Inspekcja →przetwarzanie surowe→UT →Druga obróbka cieplna →przetwarzanie końcowe →Inspekcja |

| Standardy UT | ASTM A388 lub EN10228, itp. |

- Raport z badania uderzeniowego i obliczenia wytrzymałości z informacjami dotyczącymi zastosowanych materiałów

- 100% sprawozdania z badania NDT (bezniszczalnej kontroli) stali, rury i elektrody

- Sprawozdanie z badania promieniowania rentgenowskiego, promieniowania γ i płynnego materiału przenikającego (szwy spawalnicze)

- Raport z badań hydraulicznych w celu zapewnienia standardowego ciśnienia roboczego i bezpieczeństwa